100% pp nonwoven fabric

Product

1.Material:100% polypropylene

Nonwoven technics:Melt blown

Width:Can be cut into 17.5cm Or according client Request

Basic Weight:10-20-25-200gsm

MOQ(Tons):1 ton

Package:Packed in rolls, with 3 inch ID core inside, PE film and poly bags

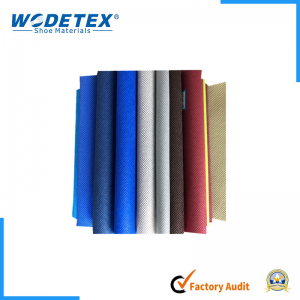

Colors:white/blue/Green

Delivery time:7 days after receiving payment

Supply Ability:200tons per month

Certifications:SGS

BFE:99%

2.Description:

Melt-blown non-woven fabric is a kind of ultrafine fiber non-woven material made by melt-blown process, raw material is food grade PP, fibre diameter can be 0.5um-2um. The product is treated with special electrostatic, characteristics of high efficiency and low resistance, comfortable and easy to adorn. Can effectively filtration and adsorption of microorganisms, viruses and extremely dust.

Medical grade mask filter can meet with Europe standard EN14638:2003 requirements, the bacterial filtration efficiency(BFE) is over 99%.

Industry grade mask filter can meet with Europe standard EN149:2001 FFP1/FFP2/FFP3 requirements, and USA standard NIOSH 42 CFE-84 requirement such as N95/N99/N100 etc.

3.Feature:

1.strong ventilation, medical non-woven fabric from 100% fiber composition porous, good ventilation.

2. good filtration, polypropylene chips without water absorption, moisture content is zero, easy to filter.

3. good heat preservation.

4. Non-toxic, non-irritating, the product is produced with FDA food-grade raw materials, without other chemical components, stable performance, non-toxic, odor-free, non-irritating skin.

5. good waterproof.

6. good flexibility, by polypropylene spinning directly into a network of thermal bonding, product strength is better than ordinary staple fiber products, strength without direction, longitudinal and transverse strength is similar.

7. Antibacterial, chemical resistance, polypropylene is a chemical passive substance, not moth, and can isolate the presence of bacteria and insects in the liquid erosion; antibacterial, alkali corrosion, the finished product does not affect the intensity of erosion.

8. Environmental friendly, non-polluting, polypropylene chemical structure is not strong, the molecular chain structure is easy to break, thus effectively and quickly into the degradation process.

4.Application:

1.Filter material Gas filter: medical masks, room air conditioners filter material Liquid filter: beverage filtration, water filtration

2.Medical & Health Material Surgical Mask: inner and outer layers with spunbond material, in the middle is melt blown fabric.

3.Environmental protection material (oil absorbent material) Meltblown nonwovens used mainly PP material. It can absorb 17-20 times bigger than its own weight of oil, in environmental protection, you can make absorption felt, oil filter, etc., are widely used in marine oil spill, plant equipment ,sewage treatment and so on.

4.Clothing Materials meltblown nonwovens by the microfiber into a net, so its very soft feel. And the fabric of small aperture, high porosity, with very good wind resistance and good air permeability, light weight, is currently doing the best material for clothing insulation materials.